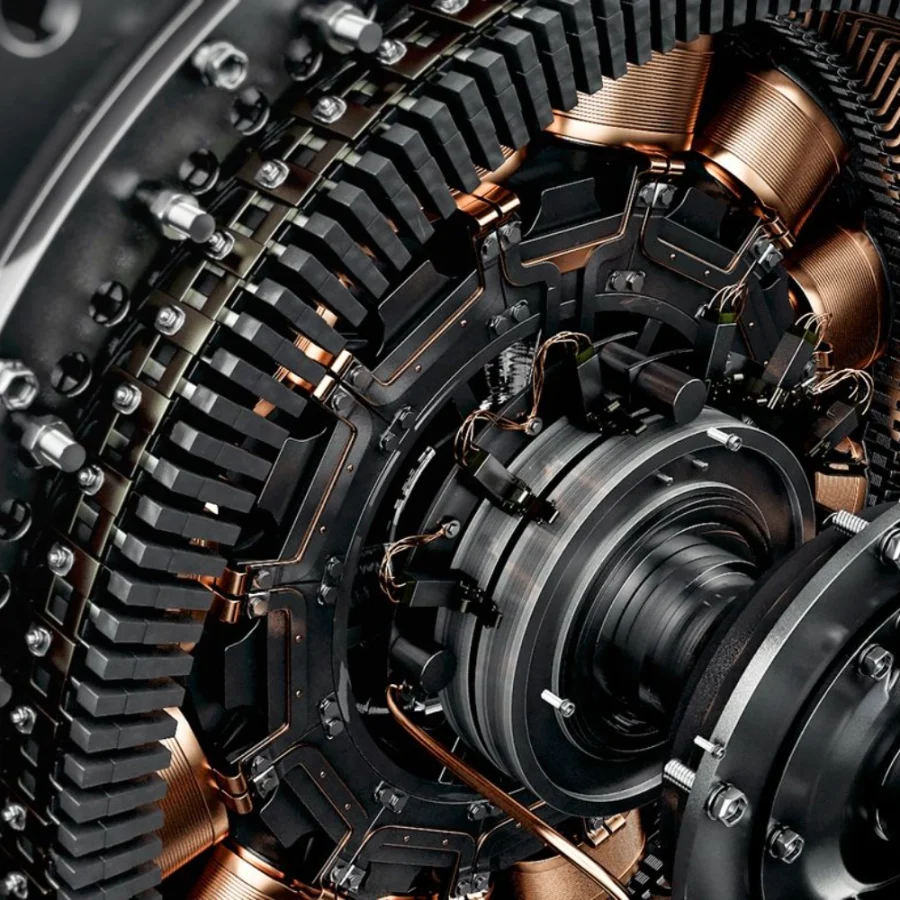

Limitless Solutions in Functionality Mechanical Design!

The Power of Motion The Nuances of Mechanical Design

Mechanical design is a term commonly used in mechanical engineering or similar engineering disciplines. It refers to the processes of designing, developing, and optimizing a mechanical system. Mechanical design typically encompasses the physical structures and components of a product, machine, or system.

Mechanical design involves the engineering field that includes the design process for machines, devices, vehicles, or other mechanical systems. It is a process that determines the physical structure, component placement, material selection, dimensions, and other technical details of a product. The goal of this design process is to ensure that the product is functional, reliable, cost-effective, and manufacturable. Mechanical design is a concept used across a wide range of industries, including automotive, aerospace, energy, consumer electronics, and many others.

Mechanical design involves the engineering field that includes the design process for machines, devices, vehicles, or other mechanical systems. It is a process that determines the physical structure, component placement, material selection, dimensions, and other technical details of a product. The goal of this design process is to ensure that the product is functional, reliable, cost-effective, and manufacturable. Mechanical design is a concept used across a wide range of industries, including automotive, aerospace, energy, consumer electronics, and many others.

Our Working Processes

Product Design Planning

The mechanical design process begins with determining the requirements of a product and clearly defining design objectives. At this stage, the product's functionality, performance, cost, and other critical factors are considered.

Mechanical Analysis and Modeling

Mechanical design includes strength analysis, durability analysis, and thermal analysis of the product. Using mechanical engineering software, a 3D model of the product is created and analyzed. This step allows for the preliminary evaluation and improvement of the product's performance.

Material Selection and Manufacturing

In the mechanical design phase, selecting appropriate materials is crucial. Material properties, durability, weight, cost, and manufacturing processes are considered to choose the most suitable material. Additionally, the manufacturing processes and techniques for the product are determined.

Prototype Production and Testing

The mechanical design process involves the production of a prototype and testing phase. This stage evaluates how the design performs in practice. The prototype allows for the assessment of mechanical features, assembly processes, ease of maintenance, and user-friendly design.

Optimization and Improvement

Based on data from prototype tests, design improvements and optimizations are made. Changes necessary to enhance the product's performance, reduce costs, or optimize manufacturing processes are implemented.

Documentation and Production

In the final stage of the mechanical design process, detailed documentation of the successfully tested and optimized design is prepared. This documentation includes instructions and information required for the production process. Having comprehensive documentation of all aspects of the design before transitioning to production helps ensure a more organized and successful manufacturing process.